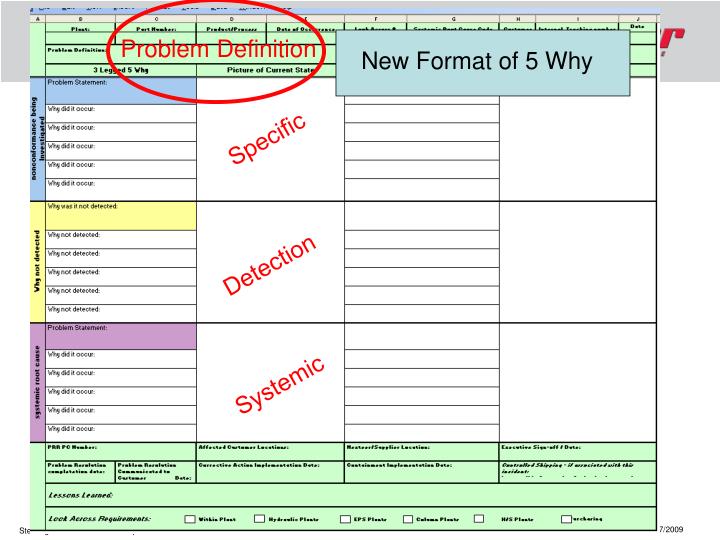

3 Legged 5 Why Template

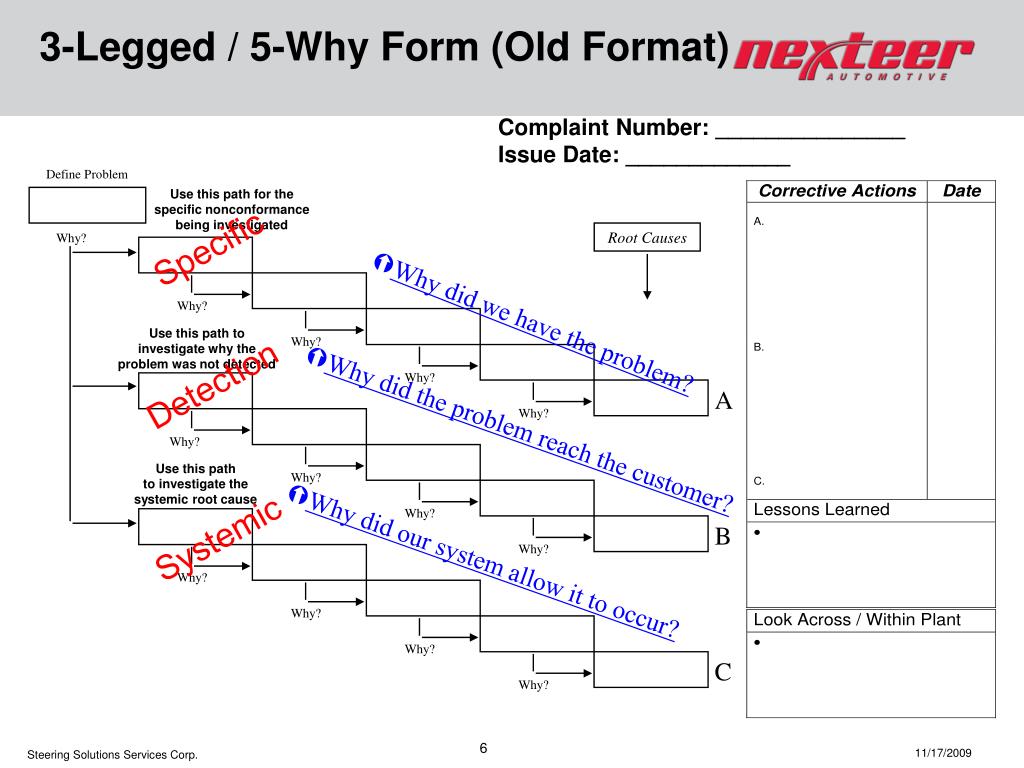

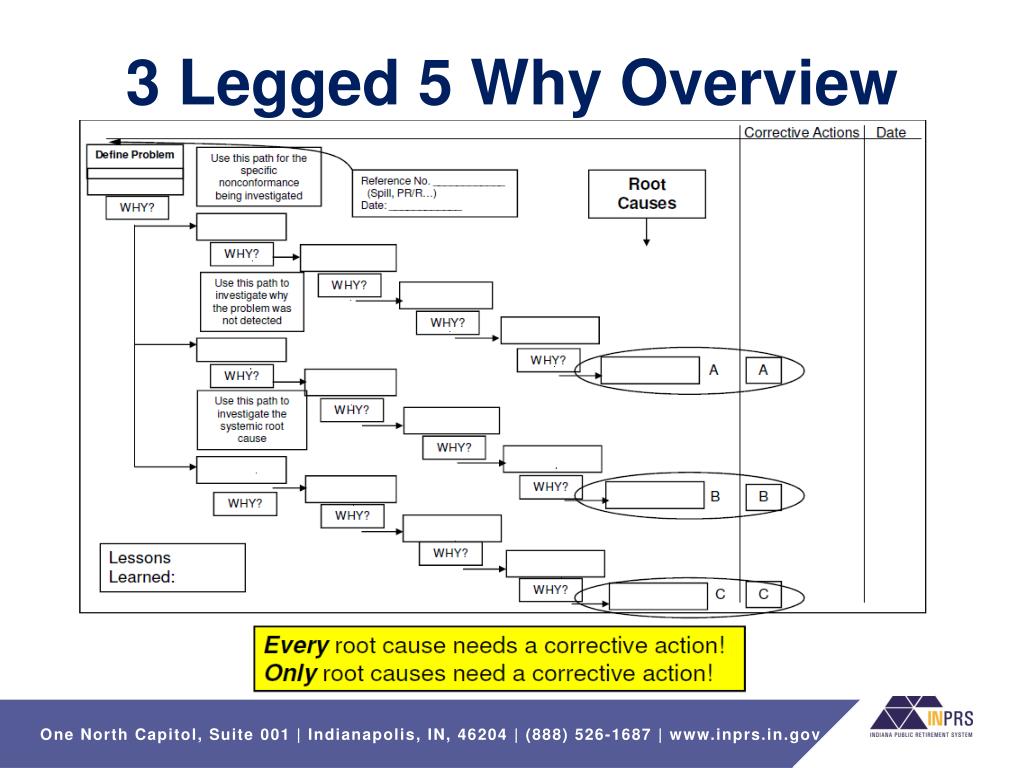

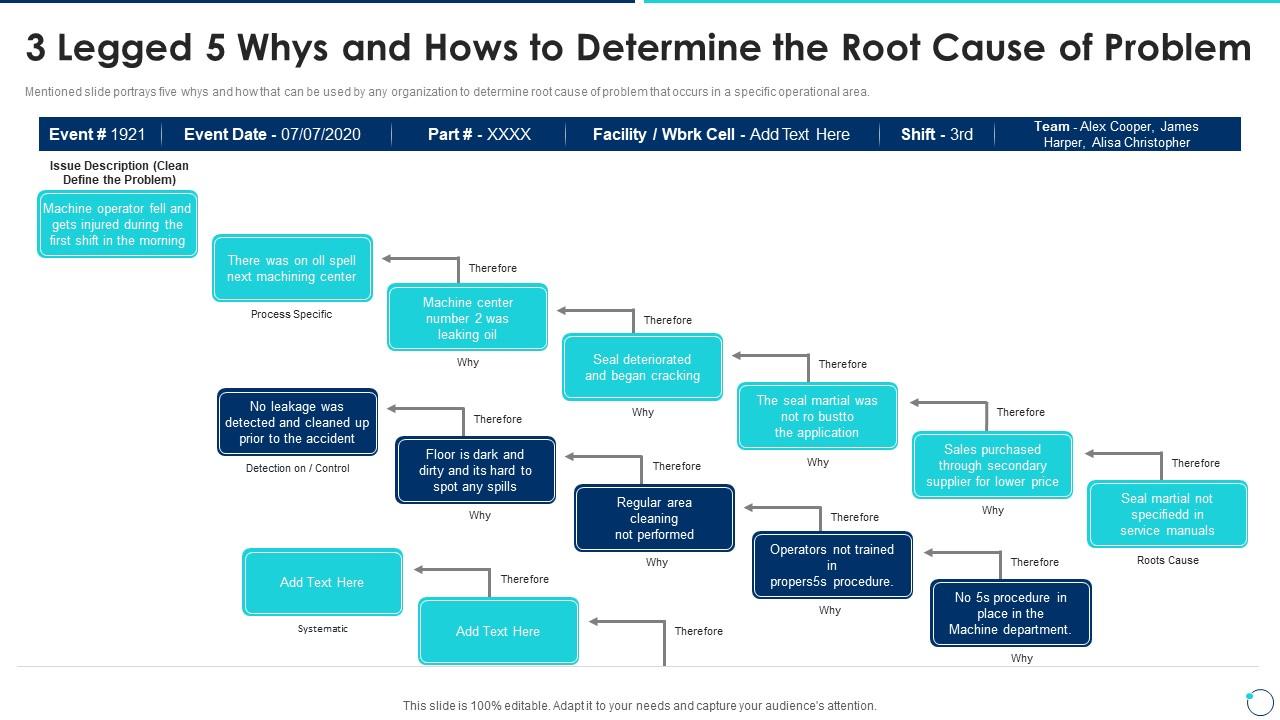

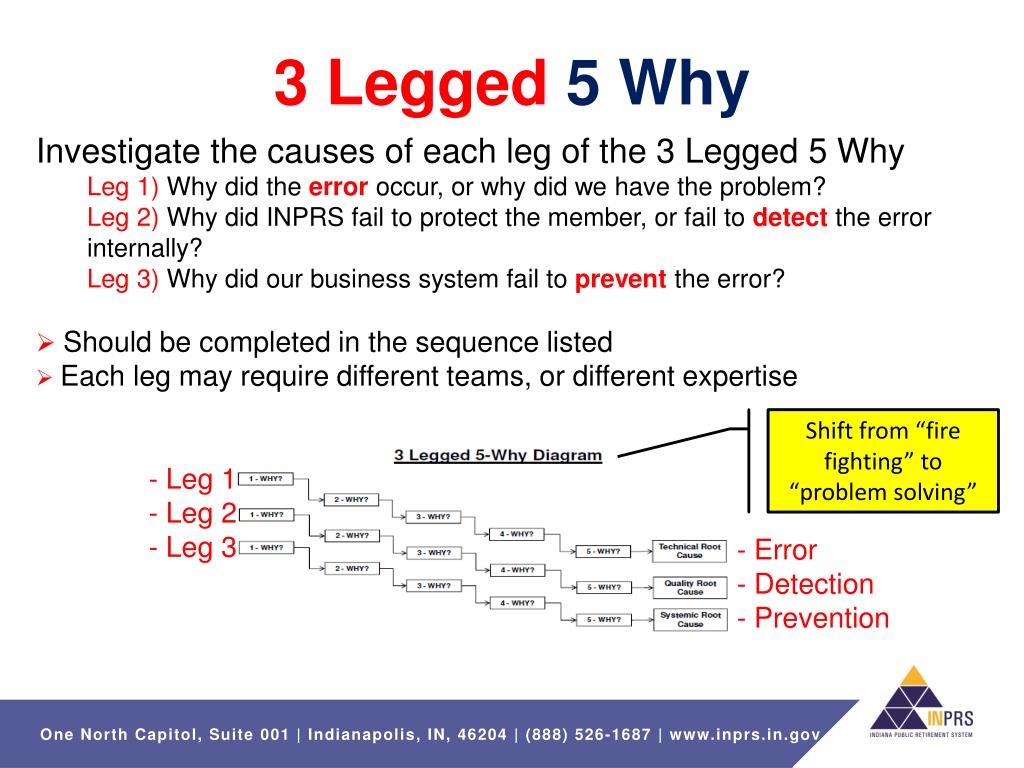

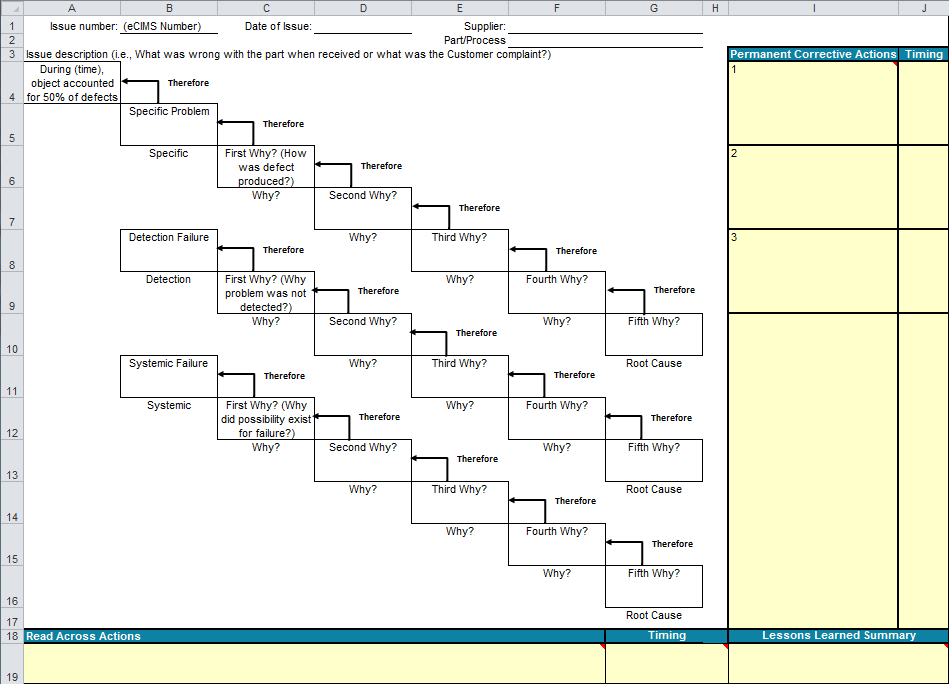

3 Legged 5 Why Template - Web ðï ࡱ á> þÿ u. Web learn how to use the 5 whys quality tool—a simple yet effective technique for determining the root cause of a problem. The kingdom and the nail 6/15/2009 ; (ecims number) date of issue: However, there are three distinct sets of five why questions:. It was made popular as part of the toyota production system. Web 3 legged 5 why picture of current state corrective actions / owner / target date picture of corrected state how problem was created problem description: Tow hitch is missing weld nut. Web this 5 whys template provides a structured approach for listing your 5 whys answers until you find the root cause of the problem. If you still don't have the system, you need to establish one in order. It was made popular as part of the toyota production system. Web 3 legged 5 why picture of current state corrective actions / owner / target date picture of corrected state how problem was created problem description: Using the 3 x 5 whys: 3 x 5 why direct cause (what immediate cause led to the nonconformance?) fishbone cause theprinciple behind. Issue description (i.e., what was wrong with the part. (ecims number) date of issue: Watch a team implement this method and help them arrive. Web definition the five whys analysis is a procedure suggested by masaaki imai for troubleshooting problems. It was made popular as part of the toyota production system. Web the 5 why method is simply asking the question “why” enough times until you get past all the symptoms of a problem and down to the root cause. 3rd issue description (clearly define the. Web up to $3 cash back second why third why fourth why fifith why sixth why seventh why eighth why. Web page 10 and 11:. Further probing might reveal that the operator had not been properly trained on the. Web page 10 and 11: Web learn how to use the 5 whys quality tool—a simple yet effective technique for determining the root cause of a problem. Tow hitch is missing weld nut. Why was the batch defective? Web 5 whys root cause analysis template click here to create 5 whys templates in smartsheet any articles, templates, or information provided by. (why did we have an escape?): 3 x 5 why direct cause (what immediate cause led to the nonconformance?) fishbone cause theprinciple behind the 5 why is to ask why until one cannot ask why. Web apr. However, there are three distinct sets of five why questions:. Web 5 whys root cause analysis template click here to create 5 whys templates in smartsheet any articles, templates, or information provided by. Part was produced with inadequate therefore fusion of weld projections. Let’s consider a hypothetical scenario where a manufacturing company has produced a defective batch of products. Web. The machine calibration was off. 3rd issue description (clearly define the. Further probing might reveal that the operator had not been properly trained on the. Using the 3 x 5 whys: Web 5 whys root cause analysis template click here to create 5 whys templates in smartsheet any articles, templates, or information provided by. Web learn how to use the 5 whys quality tool—a simple yet effective technique for determining the root cause of a problem. 1/1/2017 part # n/a facility / work cell b52 shift: Web page 10 and 11: Issue description (i.e., what was wrong with the part. The kingdom and the nail 6/15/2009 ; It was made popular as part of the toyota production system. Web page 10 and 11: Web ðï ࡱ á> þÿ u. The machine calibration was off. (ecims number) date of issue: Web 3 legged 5 why picture of current state corrective actions / owner / target date picture of corrected state how problem was created problem description: How was the problem introduced? Web definition the five whys analysis is a procedure suggested by masaaki imai for troubleshooting problems. The machine calibration was off. Web apr 4, 2012 #3 hi in systemic,. 3 leg 5 why analysis template. Web 3 legged 5 why picture of current state corrective actions / owner / target date picture of corrected state how problem was created problem description: It allows to support your answers with evidence. Web ðï ࡱ á> þÿ u. Further probing might reveal that the operator had not been properly trained on the. Web learn how to use the 5 whys quality tool—a simple yet effective technique for determining the root cause of a problem. Watch a team implement this method and help them arrive. Web page 10 and 11: The machine calibration was off. Was there a failure or weakness in a process,. However, there are three distinct sets of five why questions:. Why was the batch defective? Using the 3 x 5 whys: (how was the specific problem (2nd leg): The 5 why method is often. It was made popular as part of the toyota production system. Issue description (i.e., what was wrong with the part. Part was produced with inadequate therefore fusion of weld projections. If you still don't have the system, you need to establish one in order. Web 5 whys template.5 Why S Technique And Cause And Effect Analysis Gambaran

3 Legged 5 Why QualityOne

PPT 3 Legged 5 Why Analysis PowerPoint Presentation, free download

PPT 5Whys A Simple and Effective Problem Solving Tool Tom Farrer

3 Legged 5 Whys And Hows Collection Of Quality Control Templates Ppt

PPT 5Whys A Simple and Effective Problem Solving Tool Tom Farrer

Root Cause Analysis Tool. 3 Legged 5 Why.

PPT 3 Legged 5 Why Analysis PowerPoint Presentation ID6710152

Three Legged Five Why Template for Excel 3L5W

5 Why & 5 How Root Cause Analysis QualityOne (2023)

Related Post: